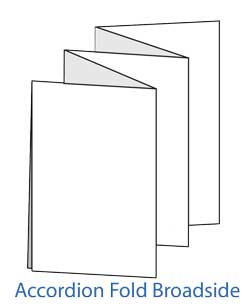

The Problem: Broadside accordion folds, or single sheet accordion folds on cover stock, each require scoring in the first section before the right angle fold. By broadside, we are referring to a fold in 1/2 in the first section, then folds into multiple panels in the right angle. Each score must line up precisely with the fold, and each fold plate must be set to create equal size panels.

Of course all the scores must be perfectly positioned and must register. If you don't have this to start with, you'll fight quality all day long. Inexperienced folding machine operators often mistakenly chase fold plate settings or fold roller pressure adjustments, when the real culprit is one or two misaligned scores.

A quick old-timer tip for making the scores visible...apply a dark crayon or felt tip marker to your Tri-Creaser Creasing Rib. This makes the score visible and it wears off after several sheets.

Once the scores are set, the operator usually sets the right angle folds with the scored sheets. As soon as the fold plate appears to be set correctly, they'll move on to the next plate. However, it's not surprising to find that the actual fold plate setting can be up to 1/4" away from the score! The reason: for this type of fold, the scores are typically very strong, and once you get the fold plate set within about ¼” from the score, the sheet will buckle at the weak spot…in this case on the score. It may do so for a few sheets or even a few hundred sheets.

So although the folder may seem to be set, one plate just slightly off can have an intermittent impact on folding, and one or more folds can be affected without any apparent rhyme or reason.

A Solution:

- Before running any of the "live" pre-scored sheets, cut down sheets of single thickness stock to the exact same size of the piece as it is coming out of the first section. If you're already running a single sheet cover stock, just cut down text stock to the same size.

- Re-set the fold roller calipers for this setup stock.

- Hand feed one sheet at a time, and set fold plates, one at a time. Be sure they are folding consistently and squarely.

- Re-set fold roller calipers to the live job. Run several sheets of the live job. It should fold perfectly.

It's an extra step that takes at most 10 minutes to accomplish, but it's saved us countless hours of troubleshooting time over the years, and we are sure it will do the same for you.

- Categories:

- Bindery - Finishing

When he’s not busy helping printers become more profitable with unique bindery equipment accessories, Andre Palko writes on the subject of print finishing at the Bindery Success™ Blog. A print industry veteran of 30+ years as well as founder and President of Technifold USA, Inc., his articles are regularly featured in many print and online trade publications. You can contact him at andre@technifoldusa.com.

Compact Bindery Solutions for In-plants

Compact Bindery Solutions for In-plants

Small Bindery Equipment to Check Out at the Expo

Small Bindery Equipment to Check Out at the Expo

Duplo USA Bringing Print Embellishment, Finishing Solutions to Expo

Duplo USA Bringing Print Embellishment, Finishing Solutions to Expo

Expo Visit Inspires Bindery Upgrades at Texas In-plant

Expo Visit Inspires Bindery Upgrades at Texas In-plant

Marketing Mail Innovation Showcase at National Postal Forum

Marketing Mail Innovation Showcase at National Postal Forum

Smart Automation in Finishing on Display at Innovationdays

Smart Automation in Finishing on Display at Innovationdays