The type of folding machine we’re talking about is seen in thousands of small quick printing shops and digital printing departments around the world. It has two fold plates along with either a friction or air feeder. Some of the more popular ones include Baum 714, Morgana UFO, MB CAS, Challenge Medalist, Martin Yale and many more. They handle the most common types of folds such as letter fold, accordion folds, double parallel, and single folds.

If that’s the only kind of folder you own, every now and then you probably encounter a job that requires more than the two folds supplied by these versatile machines. Here’s one way to expand your folding capabilities without necessarily needing another machine.

You can take the basic double parallel fold (see diagram) and turn it into at least four other folds:

You can take the basic double parallel fold (see diagram) and turn it into at least four other folds:

- A four-panel accordion fold

- A double gatefold

- A roll fold

- A three-panel accordion with a fold-in panel

It requires hand-work to accomplish this, but don’t be afraid of that word. It’s fashionable to dismiss hand-work in this automated digital age, yet doing so can cost you opportunity.

Hand folding is very fast once you get into the swing of it. You can easily do a few hundred or even a few thousand re-folded pieces in short order.

Of course we’re assuming you don’t have a right angle section. If you do have one, you can do all but the gate fold by running the right angle straight in line rather than at a right angle.

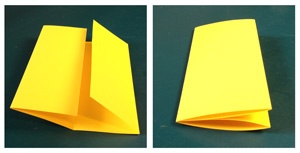

The Double Gate Fold

The Double Gate Fold

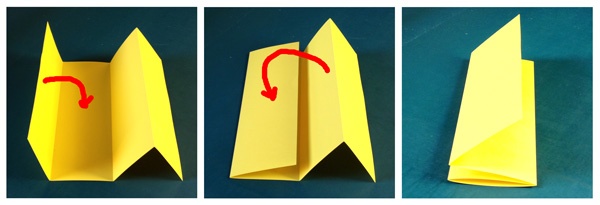

Take your double parallel and open it up. Re-fold into a single gatefold as shown at right. Then fold it in half for the double gate fold.

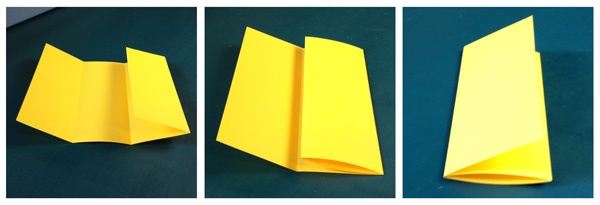

The Roll Fold

Open up the double parallel fold as shown. Begin by “rolling” the three folds one at at time, from one side to the other as shown below.

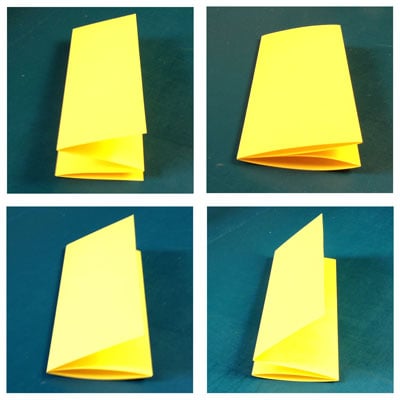

The 4-Panel Accordion Fold

The 4-Panel Accordion Fold

This one is easy. Simply flip the front page of your double parallel around to the back (photo on right) and you now have a 4-panel accordion.

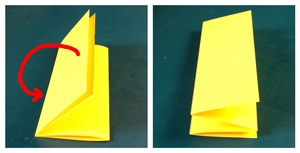

The 3-Panel Accordion with a Fold-In

Open up the double parallel as shown. Now fold the left panel in. Now fold the right two panels on top. (photo below) All the folds are in the same direction in the original and in the re-fold, so this goes quickly.

There are two important cautions about re-folding jobs like this. First, be sure that your double parallel fold is set precisely and correctly. When you re-fold it, all the panels should be able to fold easily without any buckling. For instance, if the inside panels on your gatefold are too long, you won’t be able to do the final double gatefold. So carefully check your double parallel fold and re-fold a handful of samples before you commit to the entire run. Check this frequently throughout the run.

Secondly, be sure your fold quality is consistent throughout the run. These types of folds require accuracy. If you fold on a bleed, be sure everything is cut correctly and folds correctly in the final piece. If folding consistency is in doubt on your machine, don’t do a re-fold job like this. Either get the folder tuned up or upgrade to a better machine.

Make a Second Pass

Depending on the fold requirements, you might be able to make a second pass through the folder to do more folds. By this I mean that you fold the job then feed the folded sheets through the machine a second time for an additional fold. Bear in mind however, that you’ll need to score the paper for any type of right angle fold.

If your second pass is another parallel fold you should be OK without a score as long as you can feed the pre-folded piece. Not every machine is capable of re-feeding a folded sheet. Check with the manufacturer, your technician, or just test it for yourself.

Two-pass folding is OK for occasional, low-volume work. If you plan to do a lot of two-pass work, it’s far better to add a right angle section so you can do it all in one pass. Or if you plan to do a lot of parallel folding with more than two folds, you’ll definitely want to upgrade to a bigger four-plate folding machine.

As with all things bindery, be sure to test your idea before committing to it. As always, we welcome your stories, comments and suggestions below

- Categories:

- Bindery - Finishing

When he’s not busy helping printers become more profitable with unique bindery equipment accessories, Andre Palko writes on the subject of print finishing at the Bindery Success™ Blog. A print industry veteran of 30+ years as well as founder and President of Technifold USA, Inc., his articles are regularly featured in many print and online trade publications. You can contact him at andre@technifoldusa.com.

Compact Bindery Solutions for In-plants

Compact Bindery Solutions for In-plants

Small Bindery Equipment to Check Out at the Expo

Small Bindery Equipment to Check Out at the Expo

Duplo USA Bringing Print Embellishment, Finishing Solutions to Expo

Duplo USA Bringing Print Embellishment, Finishing Solutions to Expo

Expo Visit Inspires Bindery Upgrades at Texas In-plant

Expo Visit Inspires Bindery Upgrades at Texas In-plant

Marketing Mail Innovation Showcase at National Postal Forum

Marketing Mail Innovation Showcase at National Postal Forum

Smart Automation in Finishing on Display at Innovationdays

Smart Automation in Finishing on Display at Innovationdays