Value and Versatility

Steven Barrett and Evonne

Daniel show off one of the buses the in-plant improved using adhesive vinyl.

Steven Barrett has no problem being a broken record.

The assistant manager of Printing Services at the University of North Carolina-Wilmington, Barrett says when a new or challenging job comes his way, his response is almost always the same.

“We can do that,” he tells his customers.

Barrett and the rest of the Printing Services staff have taken this accommodating attitude to new heights, finding ways to serve the university that go far beyond standard print jobs. Through some creativity with signs, banners, murals and adhesive vinyl applications, the in-plant has added a signature touch to the main outdoor academic walkway, athletics displays, multiple buses, and other highly visible locations.

“I think we bring a different value now,” Barrett observes. “We’re not just a ‘get your letterhead’ and ‘get your business card’ type of shop.”

Vinyl Takes Off

Printing Services didn’t initially dive head first into the world of vinyl applications. Before that part of the business took off across campus, the in-plant used an etcher to produce stickers and made some vinyl lettering for office doors. When campus budgets tightened up during the recession, customers flinched at the high cost of purchasing wide-format printing from the outside and turned to the in-plant instead.

“That was the big turn on,” Barrett recalls. “We can do it in-house. You don’t have to go to somebody else.”

Through a partnership with a local vendor that supplies the seven-employee in-plant with the media for the signs it produces, Printing Services is able to acquire vinyl that it can cut in-house on its Graphtec FC8000 vinyl cutter.

The in-plant has been asked to make displays in several locations at the school. Recently, though, the shop took on a job that allowed it to display its vinyl work off campus. The school obtained buses to transport students from the Wilmington campus to satellite learning locations, such as the Center for Marine Science, about eight miles off campus.

The in-plant was tasked with turning the bland white buses into something that was distinctly UNCW. Using the bright colors the coastal university brands itself with and the school’s recently redesigned athletics logo, the in-plant cut all of the vinyl out to shape and adhered it to the buses.

“Evonne [Daniel], our designer, came up with four or five different designs, and this is the one they picked out,” Barrett says. “The logo on the driver’s side door, we were concerned about because it’s built out of vinyl, but that fell in place very easily. Everything else was just a matter of a little bit of time and getting things squared.”

Homecoming Debut

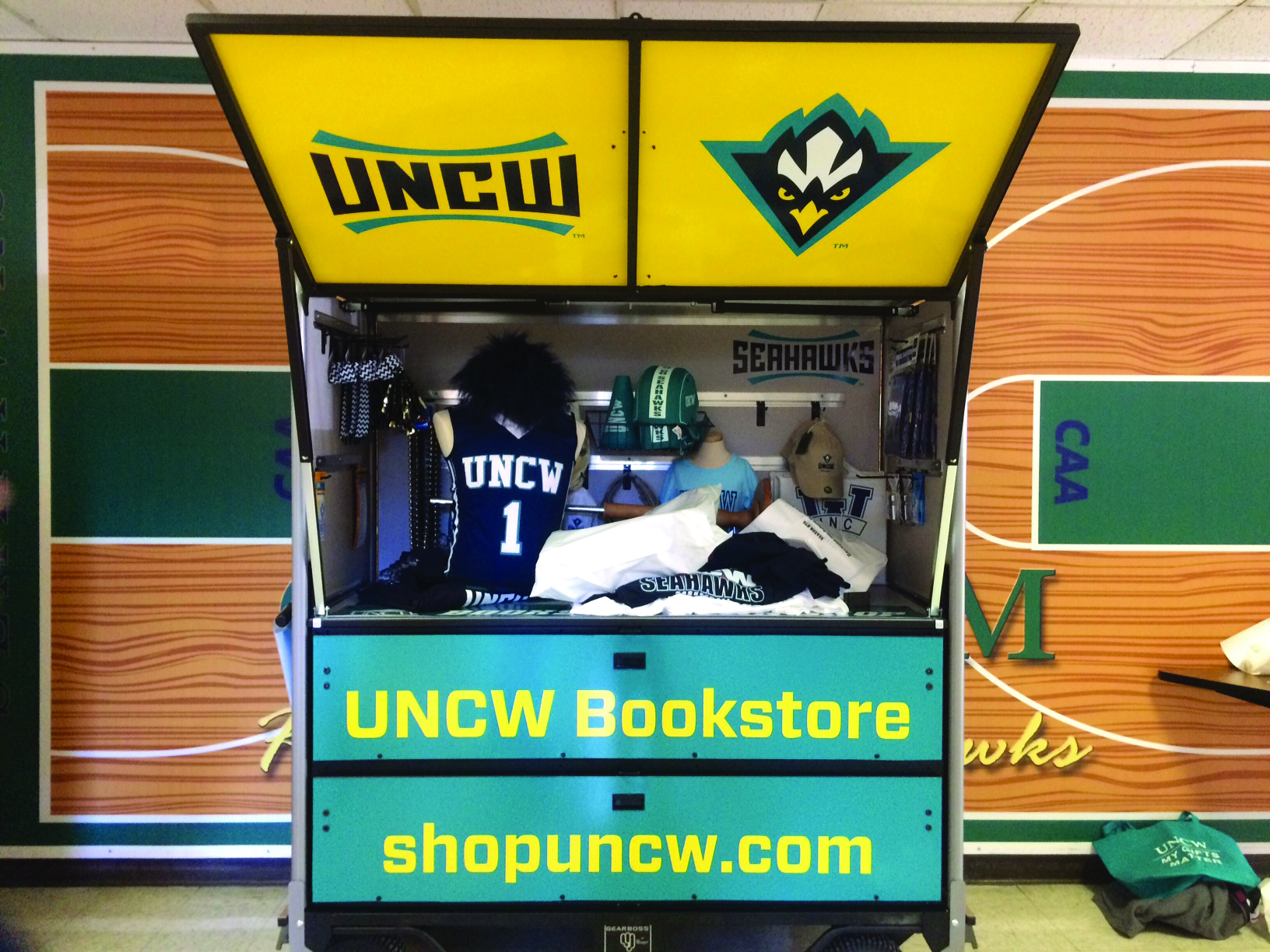

Printing Services used vinyl to spruce up this kiosk, which the athletics department uses to sell its merchandise.

Though the buses are a mobile way to display the university’s new graphic identity, Printing Services was also tasked with helping to debut the new athletics logo during the homecoming basketball game this year.

Barrett explains that the athletics department had acquired a kiosk it could to use to sell its newly branded merchandise and wanted the in-plant to spruce it up with the new logo. Again, using the Graphtec and several pieces of vinyl, Printing Services covered the kiosk in the school’s blue, teal and yellow colors and displayed the new Seahawks logo prominently.

“We decided we wanted the cleanest look possible,” Barrett states. “That’s when we decided to go with vinyl. Nothing on that kiosk is printed. It’s built out of vinyl material.”

Creative Wide-format Work

While the Graphtec vinyl cutter has helped the in-plant take on some creative, outside-the-box jobs, Printing Services has also used its Mutoh Valuejet 1204 wide-format printer to bring in some creative projects as well. For example, like many in-plants, Barrett says Printing Services has realized the added value that canvas prints can provide. While the in-plant has produced several individual prints that stand alone, Barrett says Printing Services is particularly proud of a recent job it did in which it implemented canvas prints into a larger project.

After UNCW’s Auxiliary Services department had refurbished its office, Barrett says it was eager to use Printing Services to add some fresh graphics to the space and promote all of the work the department does, which includes operating the bookstore, food court, buses and various vending activities.

The in-plant produced this mural highlighting Auxiliary Services’ capabilities using a mixture of wide-format printing, vinyl cutting and canvas wraps.

Barrett says Daniel again was called upon to design the project, which was originally conceived as a large banner with a collage of different images displaying Auxiliary Services’ capabilities. But as the department learned more about all of the products Printing Services can create, the result became a mixture of wide-format printing, vinyl cutting and canvas wraps.

The backdrop, Barrett explains, is a non-permanent media that was produced on the Mutoh Valuejet. On top of that, the in-plant added an acrylic sign with vinyl lettering that reads “UNCW Auxiliary Services.” Then, several canvas wrapped prints were produced with images of Auxiliary Services’ activities.

“They wanted students coming in and getting a visual of what’s around them,” Barrett states. “These pictures are all basically of Auxiliary Services.”

A Revamped Walkway

Chancellors Walk is not only one of UNCW’s iconic landmarks; it’s where the majority of the campus’s academic buildings are located. Barrett explains that in the past, when new programs were announced, the academic departments would promote them outside of their buildings using sandwich boards.

However, the walkway is lined with light posts that, until recently, were being underutilized. The school’s ETEAL (Experiencing Transformative Education through Applied Learning) program wanted to promote itself a little differently and tasked the in-plant with providing banners to be hung on the light posts.

Using the Mutoh printer and 13-ounce banner material, Printing Services produced the banners and hung them along Chancellors Walk. While the ETEAL program received the first of these interchangeable banners, Barrett explains that going forward, academic departments will be able to “rent” a light post and have the in-plant produce a banner to promote it.

“There have never been banners on these particular light poles,” Barrett states. “It seems to be a real big hit right now.”

The Price is Right

By thinking outside the box on these types of projects, the in-plant has demonstrated the value it adds to the university, Barrett says, while completing these jobs at a discount compared to what outside printers charge. For example, the vinyl adhesive work on the buses cost the in-plant approximately $450, Barrett says; a similar job done with an outside vendor would have cost around $1,500.

Barrett explains that providing these budget-friendly services and being a versatile operation not only benefits the school, but also provides stability for the in-plant. Printing Services’ leadership, he says, is enthusiastic about maintaining a wide reach across campus to ensure its value is known.

“[Our boss] is all about getting our fingers everywhere, so if the plug was pulled, it’s going to drain a lot of things,” he says.

Cory Francer is an Analyst with NAPCO Research, where he leads the team’s coverage of the dynamic and growing packaging market. Cory also is the former editor-in-chief of Packaging Impressions and is still an active contributor to its print magazines, blogs, and events. With a decade of experience as a professional journalist and editor, Cory brings an eye for storytelling to his packaging research, providing compelling insight into the industry's most pressing business issues. He is an active participant in many of the industry's associations and has played an essential role in the development of the annual Digital Packaging Summit. Cory can be reached at cfrancer@napco.com

Innovation, Automation, and AI Take Center Stage at the 2025 Wide-Format Summit

Innovation, Automation, and AI Take Center Stage at the 2025 Wide-Format Summit

Avoiding Graphic Installation Disasters

Avoiding Graphic Installation Disasters

Roland Highlights Next-Level Systems

Roland Highlights Next-Level Systems

Infusion of Wide-Format Gear at Shippensburg

Infusion of Wide-Format Gear at Shippensburg

New Wide-Format at University of California San Francisco's In-plant

New Wide-Format at University of California San Francisco's In-plant

Wide-Format Products on Display at PRINTING United

Wide-Format Products on Display at PRINTING United