Ithaca College Adds Value With Dye-Sublimation

Sometimes, figuring out whether new technology will add value to your in-plant means just giving it the old college try. With the relatively low cost of entry for dye-sublimation equipment, a growing number of in-plants are doing just that, and discovering that printing shirts, mugs, name tags and other items is a great way to supplement their revenue while bringing value and recognition to their in-plants.

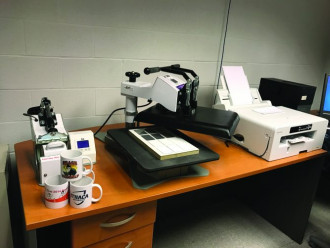

The dye-sublimation setup at Ithaca College comprises a mug press, heat press and Virtuoso SG800 sublimation printer.

For Karen Serbonich, director of General Services at Ithaca College, getting dye-sub equipment simply made sense as a way to save the college money. The college, she explains, uses silver name badges for faculty and staff and white name badges for its physical and occupational therapy clinical students. An outside company was producing these badges, costing the school $12,000 per year.

“You’re going to be spending money to make those things anyway with outsourcing,” she notes. “Why not bring it on campus?”

She got the idea after visiting another New York college that was using dye-sublimation and seeing samples of the items they were producing, including name badges. Realizing the potential cost savings, Serbonich purchased a Sawgrass Virtuoso SG800 printer, Digital Knight DK20S heat press and DK3 mug press. Since installation in June of 2016, the equipment has already paid for itself, she says.

Related story: Dye-Sublimation Saves Money for Susquehanna University

“We looked at the price to buy blanks [name tags] and ink for the 2x3˝ space, and in one year we’ve saved the school $9,000,” she says. “The initial investment for paper, ink and equipment was $4,400 and we’ve already paid for the ROI.”

But name badges aren’t the only product that the shop offers; mugs have been popular among students and departments. Serbonich says that the team would also like to test out bandanas, socks and possibly license plates, a popular product in the campus bookstore.

One piece of advice that Serbonich offers is to experiment with the amount of time a material should be in the heat press. Though there are guidelines, she explains that sometimes they might not be appropriate for the type of material you are working with.

“We found the guidelines they gave for name badges were too long,” she says. “It discolored them, so we had to keep lessening the time by a few seconds. It’s interesting, with dye-sub, it melts into the product and if you keep it in [the press] too long, the ink will start to spread and not be the sharp image that you want.”

For mugs, she says that the process necessitates the operator produce them one by one and then place the mug in water to cool it off and stop the heating process. In all, it’s approximately a five-minute process per mug. This can seem like a large investment of time when you receive a big order, but the beauty of creating mugs in-house, Serbonich says, is that the shop can produce one or 100 mugs.

“If you go off campus, there might be minimums,” she says. “If you want five mugs, we can do that.”

Though the in-plant’s dye-sub services have received a lot of word-of-mouth promotion, Serbonich says that the shop has also advertised in the college newspaper and sent out promotional messages through the internal email system. Although the in-plant doesn’t sell items in the campus bookstore yet, Serbonich explains that she is working to develop a partnership to enable that.