Graph Expo: The In-plant Perspective

A panel of Xerox users shares ideas for a packed room full of in-plant managers at IPG’s second in-plant breakfast.

In-plants were out in force at Graph Expo 2015 last month. IPG spoke with dozens of them: on the show floor, at various in-plant events, even out on the streets of Chicago.

By all accounts they were glad they attended this year. They got ideas for new services, compared and contrasted equipment from different vendors, sat down for demos of workflow and web-to-print software and got together with other in-plant managers at educational sessions. For some, the chance to network with other managers was the highlight of the show.

“I enjoyed the show tremendously; it was like being with ‘my people,’ ” remarks Catherine Chambers, director of Print & Mail Services at Alfred State, who brought two of her staff to Chicago. “We attended Graph Expo to explore options for expanding services, meet with vendors and to attend in-plant sessions.”

In-plant managers were everywhere at Graph Expo. Here, Catherine Chambers, director of Print & Mail Services at Alfred State, stops

for a chat at the Formax booth.

And there were plenty of in-plant sessions. IPG hosted three of them—two breakfasts and a lunch. The In-plant Printing and Mailing Association (IPMA) hosted a lunch. And several seminars in the show’s educational program focused squarely on in-plant topics.

“The special presentations and breakout sessions were top notch,” remarks Tim Hendrix, Oregon State Printer, who not only attended IPG’s events but led a seminar of his own covering hot technology trends.

In-plant managers on the show floor: John Sarantakos (University of Oklahoma); Debra Payne Benson (Kodak); Rob Lingard (DMBA); and Mike Lincoln (State of Colorado).

"The seminars were very informative, and it was great linking up with fellow print managers to swap stories," adds Curtis Ebdon, director of Design & Digital Print at

Fairfield University.

As for the show floor, managers were both excited and disappointed. There were fewer vendors this year, and some lamented that key technologies were missing.

“If you believe offset is dead—which I don’t—then the show confirmed your suspicions,” notes John Sarantakos, director of Printing, Mailing and Document Services at the University of Oklahoma.

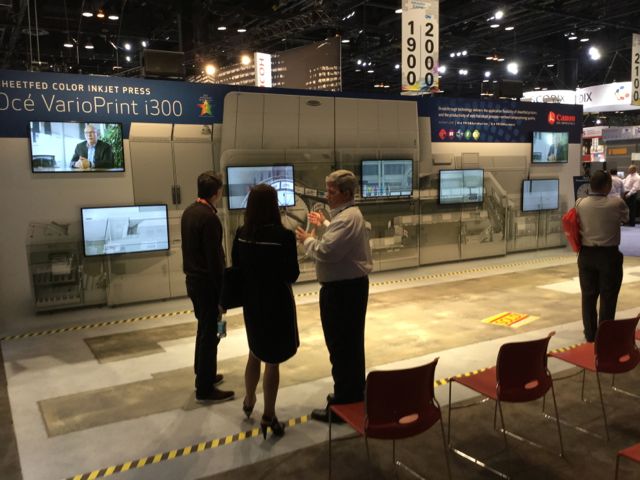

While many niche and specialty solutions were represented, says Penn State’s Abbas Badani, production inkjet—the talk of the industry—had a “very limited display.” He was disappointed with the lack of cut-sheet inkjet presses. Canon’s new Océ VarioPrint i300 cut-sheet inkjet press was not actually at the show but was demonstrated only via video. (It was shown at Canon Expo the week before.)

“In general, the show lacked any ‘wow’ factor,” observes Sarantakos.

Side-by-side Comparisons

Still, many managers were there on a mission, and valued the opportunity to compare different vendors’ equipment.

"I didn't run out of things to see or investigate in the two days I was there," remarks Ebdon. "The Xerox Rialto 900 inkjet [press] was probably the most fascinating piece of equipment I saw."

“Where else can you see equipment that does similar things that’s built and sold by four different companies?” wondered Steve Priesman, manager of Printing and Publications at Omaha Public Schools. “You can compare and contrast so easily. Where else can you talk to staff from your current vendors and troubleshoot issues or learn different ways of doing things.”

Canon introduced the imagePRESS C10000VP, which prints 100 pages per minute on stocks up to 350 gsm.

He was there to look at coil binding systems, compare Duplo and Standard equipment and ask questions about workflow to Xerox and EFI.

Some felt attendance was down this year. Others saw it differently.

“It felt like there were more people and more excitement [than] last time when

I visited two years ago,” notes Salla Vaerma-Jadlos, manager of ReproMail for the City & County of San Francisco.

Like many, she came to Graph Expo just to keep track of technology and compile a wish list to prepare for next year’s budget.

“I started seeing a clearer picture of what we might look like in few years,” she says.

She looked at digital printers, front ends, MIS and Web-to-print systems and wide-format printers.

“I was surprised to find out how affordable wide-format printers were,” she says.

Also looking at wide-format printers was Dave Hoel, production manager at the University of Minnesota—though some other things caught his eye as well.

Specialty services like garment printing piqued the interest of many in-plants. Here, visitors get a demo of the new Anajet mPower mP10i printer.

“The Scodix booth was the thing that piqued my interest,” he says. “I can see potential for our athletic department or admissions.”

The t-shirt printing demos at the Anajet booth caught his attention too.

Other mangers were also intrigued by unexpected discoveries. Hendrix came to Chicago to look at wide-format printers, workflow, MIS and Web-to-print systems, but came away impressed by Objectif Lune’s new PlanetPress Connect business process automation software and Pitney Bowes’ AcceleJet printing and finishing system.

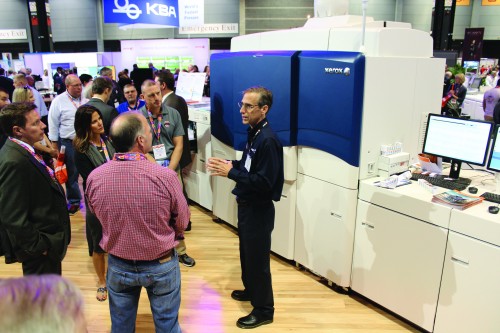

Xerox opened the doors of its new Rialto 900 inkjet press, which drew large crowds throughout the show.

Rodney Brown, from the University of Delaware, was inspired by the Foil Xpress digital foil printers from ImPress Systems and by Pro-Bind’s thermal binding equipment.

Chambers was at the show to check out mailing and inserting systems to replace her shop’s aging equipment, and to look at digital envelope printers, tabbers and production management systems. But something else caught her eye as well.

- Chapters

- descriptions off, selected

- captions settings, opens captions settings dialog

- captions off, selected

This is a modal window.

The Video Cloud video was not found.

Beginning of dialog window. Escape will cancel and close the window.

End of dialog window.

This is a modal window. This modal can be closed by pressing the Escape key or activating the close button.

This is a modal window. This modal can be closed by pressing the Escape key or activating the close button.

“I really liked Timson’s affordable tabletop digital UV coater and will definitely put it on our list,” she says.

Another UV coater from TEC Lighting impressed Tammy Dunham, manager of Print Services at Nestlé Purina, who was at the show to look at digital presses. She also spotted some interesting canvas mounting systems from GOframe. Dunham felt the show was well attended, and she had an interesting theory to explain it.

Canon’s new Océ VarioPrint i300 cut-sheet inkjet press was not actually at the show but was demonstrated via video. (It was shown at Canon Expo the week before.)

“I wonder if people from the Midwest wanted to make sure they go before it’s in Orlando next year,” she speculates.

Graph Expo’s relocation to Florida in 2016 was a recurring topic of discussion this year, with many speculating that attendance will shrivel in the Florida heat. This would be a shame, notes Badani, since attending Graph Expo is a great way to get new ideas.

“It is a great place for in-plants to see what is new and possibly affordable and actually [can] have a direct impact on their operation,” he says.

In-plant Education

It’s also a great place to go for free education. IPG’s free in-plant breakfast and lunch sessions were a hit again this year, bringing so many managers together that, for a few hours, Graph Expo felt like an in-plant conference. The first of these events was a breakfast sponsored by Canon Solutions America. Attendees heard from two speakers who discussed how in-plants can deliver more value to their parent organizations and improve their overall performance.

At a luncheon sponsored by Rochester Software Associates, in-plant managers listen to Tom Rohrbach of Progressive talk about his quest to insource more work.

Kicking off the event was Barb Pellow, group director at InfoTrends, who discussed the rising importance of using data-driven marketing and highly personalized direct mail to increase response rates. She showed examples of effective personalized mail pieces, such as a mailing from a restaurant that included a personalized map with directions from the recipient’s house. Cross-media marketing services, she said, are critical for in-plants to start offering to enhance their relevance.

- Chapters

- descriptions off, selected

- captions settings, opens captions settings dialog

- captions off, selected

This is a modal window.

The Video Cloud video was not found.

Beginning of dialog window. Escape will cancel and close the window.

End of dialog window.

This is a modal window. This modal can be closed by pressing the Escape key or activating the close button.

This is a modal window. This modal can be closed by pressing the Escape key or activating the close button.

Repeating that message was Aaron Hale, of Canon Solutions America, who demonstrated a new centralized Web-based suite of tools and resources called the Performance Resource Center created specifically for in-plant managers. It features a Cross-Media Suite that includes a pay-as-you-go, wizard-driven cross-media production tool.

Xerox Marketing Manager Allen Lea (right) interviews a panel of managers about their efforts to transform themselves from printers into value-add partners. From left: Steve Priesman, of Omaha Public Schools; Tasha Carter of YWCA of Los Angeles; Abbas Badani, of Pennsylvania State University; and Cathy Skoglund, of Arizona State University.

Hale took the audience through the seven simple steps required to launch an email campaign, then showed off other in-plant tools like a justification calculator, an open house kit and the Performance Challenge, a Web-based operational workflow assessment tool designed to help in-plant managers gain insight into how well their operational processes are performing by measuring against industry benchmarks.

Panel of Managers

On Tuesday morning, scores of in-plant managers got together again to network and listen to presentations during a breakfast meeting sponsored by Xerox. In-plant managers filled nearly every seat in the room to hear Xerox Marketing Manager Allen Lea interview a panel of managers about their efforts to transform themselves from printers into value-add partners. On hand were Cathy Skoglund, of Arizona State University; Abbas Badani, of Pennsylvania State University; Steve Priesman, of Omaha Public Schools; and Tasha Carter of YWCA of Los Angeles.

Each revealed the steps they have taken to transform their operations and shared some of their innovative projects, such as a variable data mailing Priesman created using XMPie software and sent to 18,000 parents in his district telling them the time and location of their children’s bus stops, as well as the school name, principal name and contact information. The next step, he said, will be sending an electronic version to parents who have provided an email address.

Badani related how the e-commerce print procurement site he created has improved his in-plant’s strategic relevance, while cutting costs and providing more transparency. All vendors must bid electronically through the PSU Print Portal. Jobs are awarded based on which vendor offers the best value. Because the in-plant has the opportunity to see all the work, he said, it can position itself to deliver value where it can be most effective.

Skoglund discussed how her student-run in-plant is rebuilding and refining its processes and rebranding itself to the university with a 13-touchpoint marketing campaign using all channels of communication. She talked about the shop’s new Infigo Web-to-print system, its growing wide-format printing business and the new Xerox iGen4 Diamond press it is adding.

Seven-step Analytical Process

Just a few hours later, managers met again for lunch, this time to hear Tom Rohrbach of Progressive Insurance discuss his efforts to insource the variable data and creative work that is currently being outsourced. In a session sponsored by Rochester Software Associates, Rohrbach shared the seven-step analytical process his in-plant is using to determine whether work can be produced cost-effectively in-house.

In-plant managers fill the room for one of several in-plant events at Graph Expo, this one a luncheon hosted by the In-plant Printing and Mailing Association.

He and his team have taken a careful look at the shop’s existing equipment to decide whether they can cost effectively produce the outsourced work. They ask themselves whether new equipment would allow them to produce the work internally at a better cost and with better service. They also analyze and refine their cost model. Rohrbach stressed the need for in-plants to have “champions” among their customer base to help stress the value they provide.

- Chapters

- descriptions off, selected

- captions settings, opens captions settings dialog

- captions off, selected

This is a modal window.

The Video Cloud video was not found.

Beginning of dialog window. Escape will cancel and close the window.

End of dialog window.

This is a modal window. This modal can be closed by pressing the Escape key or activating the close button.

This is a modal window. This modal can be closed by pressing the Escape key or activating the close button.

Many of the in-plant managers who attended these events also gathered for a luncheon on Monday hosted by the In-plant Printing and Mailing Association. Howie Fenton of InfoTrends gave a presentation revealing the results of an ongoing in-plant survey, and then moderated a panel of three in-plant managers—Tammy Slone of Cedarville University, Curtis Ebdon of Fairfield University, and Brian Wadell of the University of California-Davis—who shared innovative practices they use to bring more work into their shops.

Fenton had previously led another educational session at Graph Expo, called “The Secrets of Leading In-plants” in which he used InfoTrends data to show trends among in-plant leaders.

In another seminar, Elisha Kasinskas of Rochester Software Associates moderated a panel of four managers—Mike Lincoln (State of Colorado), Karen Meyers (Michigan Farm Bureau), John Sarantakos (University of Oklahoma), and Andrew Yee (Dynamic Funds). They discussed how they stay relevant and satisfy customers, the types of new work they are adding and the tools and technology they use to grow their operations.

Bob has served as editor of In-plant Impressions since October of 1994. Prior to that he served for three years as managing editor of Printing Impressions, a commercial printing publication. Mr. Neubauer is very active in the U.S. in-plant industry. He attends all the major in-plant conferences and has visited more than 180 in-plant operations around the world. He has given presentations to numerous in-plant groups in the U.S., Canada and Australia, including the Association of College and University Printers and the In-plant Printing and Mailing Association. He also coordinates the annual In-Print contest, co-sponsored by IPMA and In-plant Impressions.

Leadership Change at Tecnau Brings Back a Familiar Face

Leadership Change at Tecnau Brings Back a Familiar Face

Compact Bindery Solutions for In-plants

Compact Bindery Solutions for In-plants

Small Bindery Equipment to Check Out at the Expo

Small Bindery Equipment to Check Out at the Expo

Duplo USA Bringing Print Embellishment, Finishing Solutions to Expo

Duplo USA Bringing Print Embellishment, Finishing Solutions to Expo

Expo Visit Inspires Bindery Upgrades at Texas In-plant

Expo Visit Inspires Bindery Upgrades at Texas In-plant

Marketing Mail Innovation Showcase at National Postal Forum

Marketing Mail Innovation Showcase at National Postal Forum